Tel: 0512-68022751

Email: hengda@szhdjh.com.cn

Address: 6th floor, Building 8, Hengfuwei Industrial Park, Mudu Town, Suzhou City

In the pharmaceutical industry, the requirements for medicinal nitrogen are very high, and high-purity nitrogen is required to meet the production needs. The difference between the medicinal nitrogen generator and other nitrogen generators is that the GMP standard, the international standard of the pharmaceutical industry, stipulates that the parts in contact with drugs or liquids are made of stainless steel and require sterilization. The nitrogen generator needs to be made of stainless steel, and the nitrogen outlet needs to be equipped with a sterilizing filter and other devices. Because pharmaceutical factories have high requirements for nitrogen generators, pharmaceutical nitrogen generators generally use high configuration. It is understood that with the improvement of GMP standards, many nitrogen generator industries have also made efforts in this regard, and many high-purity pharmaceutical nitrogen generators that meet the standards have appeared on the market. Medicinal high-purity nitrogen generator can be widely used for nitrogen protection in synthetic medicine, pure nitrogen isolation in bioengineering, nitrogen filling and sealing in preparation production, such as large infusion, water injection, powder injection, freeze-dried agent, etc. Use nitrogen directly.

First, At present, there are roughly three ways to provide nitrogen in pharmaceutical production, namely: nitrogen supply from cylinder nitrogen, nitrogen supply from liquid nitrogen gasification, and medicinal nitrogen generator.

① The nitrogen purity provided by the steel cylinder is low (generally 99.5%~99.9%), and contains harmful impurities such as microorganisms and pyrogens, which cannot ensure the requirements of GMP verification for nitrogen. The requirements for sterile products are dust-free, microorganism-free and pyrogen-free, which is exactly what it is difficult to guarantee for nitrogen supplied by cylinders. The cost of nitrogen is the highest, and it requires more labor and reserves for occasions with a slightly larger amount, which is inconvenient to use.

②The purity of liquid nitrogen can meet the process requirements, but in the process of sub-packaging and transportation, the purity is easily reduced due to the pollution of equipment, accessories, materials and other factors. At the same time, it is difficult to meet the confirmation of installation, cleaning and disinfection during the preparation process of pipelines and other devices and the exchange of storage tanks, and there are unverifiable deficiencies in nitrogen microorganisms, heat sources and other items. Therefore, the use of liquid nitrogen Purity and dust content are also difficult to ensure the requirements of GMP verification, and the cost of nitrogen is high.

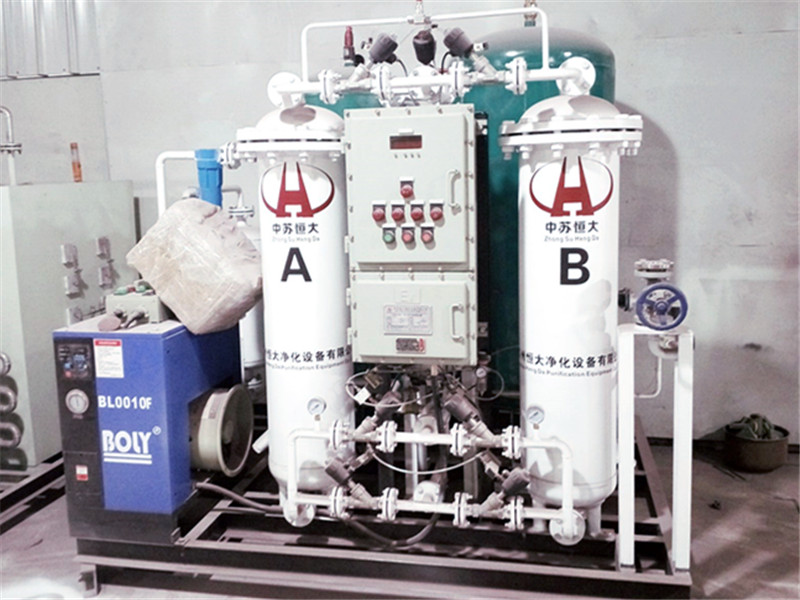

③The high-purity medicinal nitrogen generator includes three systems: compressed air treatment system, PSA nitrogen generation system and nitrogen dust removal, odor removal, sterilization purification system. The nitrogen generator adopts low-carbon austenitic stainless steel container pipes and closed casings, as well as advanced and perfect nitrogen generation technology and unique and simple structure design; the nitrogen purification filter group includes high-efficiency dust removal filters, high-efficiency odor removal filters, Bacterial filter. After nitrogen treatment, the product can be dry (dew point <-45℃), oil-free (oil content <0.001ppm), filtration accuracy 0.01um, odorless and sterile, and 100% filter out bacteria and bacteriophages. Meets cGMP requirements for sterile formulation production.

According to the requirements of GMP for nitrogen verification, the quality control of the nitrogen preparation process is the source guarantee for the safety and reliability of the nitrogen supply process. This is because the purpose of GMP is to ensure that every link in the whole process of drug production is bound by regulations and standard documents, so that the quality of the final product can be safe, effective and uniform. Therefore, gas supply methods such as ordinary steel cylinders and liquid nitrogen will be gradually eliminated by the pharmaceutical industry, and replaced by high-purity, high-quality and high-clean pharmaceutical high-purity nitrogen generator gas supply methods.

Second, Analysis of Influence on the Stability of High-purity Nitrogen Generators for Medicinal Use

Medicinal high-purity nitrogen generators are prepared by the PSA principle. Whether this type of nitrogen generators can operate stably for a long time and produce nitrogen that meets technical requirements is a matter of concern. There are three main factors that affect the stability of nitrogen generators. aspects:

(1) Carbon molecular sieve: It is the core and key of PSA nitrogen generator. Nitrogen production technology requires carbon molecular sieves with good strength, high nitrogen yield, and high nitrogen purity and recovery rate. The quality and performance of carbon molecular sieves are the key, but the selection of carbon molecular sieves is also very particular.

(2) Design of the nitrogen generator: The design of the nitrogen generator is also very particular. If the structure is not properly designed, the molecular sieve will be beaten and rubbed against each other due to the impact of high-speed airflow, resulting in powder failure.

(3) Oil removal, dust removal and filtration: Due to the existence of air pollution, the oil vapor in the air is easily adsorbed by carbon molecular sieve, and it is difficult to desorb, filling the micropores and making the molecular sieve ineffective. In addition, although water is not fatal to carbon molecular sieves, it will increase the "load" of carbon molecular sieves, that is, affect its ability to adsorb O2, CO2 and other gases

Third, Analysis of the internal components of the nitrogen generator

What are the components of the air separation nitrogen generator control system? According to the editor's knowledge, there are air compressors specially used for compressed air. What other components are there?

1. Electrical control system: It consists of PLC system, instrument touch screen, and control valve solenoid valve.

2. Air buffer tank: It is composed of air storage tank, valve, etc. It is mainly used to ensure the stability of gas consumption.

3. Nitrogen buffer tank: It is composed of nitrogen storage tank and valve to store nitrogen, mainly to ensure the stability of gas consumption.

4. The main engine of the nitrogen generator: it consists of two adsorption towers filled with carbon molecular sieves and an automatic control program-controlled valve, which can be said to be the core of the nitrogen generator.

5. Air purification system: It is composed of cold dryer, filter, oil removal filter, etc.

Fourth, the application scope and role of nitrogen-filled packaging

Nitrogen-filled packaging is rapidly replacing the traditional Chinese vacuum system packaging, and is used in the packaging of different fried foods, puffed foods, baked goods, fresh tissue sliced agricultural products, special cheese and fresh meat. The taste, taste and nutrition of my country's food, as well as its application research enterprises are expected to be further improved and developed. Nitrogen generator is a nitrogen generator designed and manufactured according to pressure swing adsorption technology. The nitrogen generator manufacturer uses air as the raw material, uses high-quality carbon molecular sieve as the adsorbent, uses the principle of pressure swing adsorption (PSA), and uses the molecular sieve full of micropores to selectively adsorb air to achieve the purpose of oxygen and nitrogen separation.

The deterioration of food is mostly caused by the oxidation technology reaction under the participation of O2 in the society, and promotes the reproduction of microorganisms and bacteria in my country, which leads to the spoilage of Chinese food enterprises. The nitrogen generator manufacturer uses air as the raw material, uses high-quality carbon molecular sieve as the adsorbent, uses the principle of pressure swing adsorption (PSA), and uses the molecular sieve full of micropores to selectively adsorb air to achieve the purpose of oxygen and nitrogen separation. As a suffocating inert N2 has suffocating and inhibiting effects on bacterial reproduction in food, the purpose of using N2 is to eliminate O2, slow down the oxidation of food and the role of the respiratory system, and N2 in water and The solubility in oil is small, and the adsorption capacity of food on N2 is relatively small. Therefore, it can be used as a kind of gas for students with good food preservation and preservation.

Further, the shape of the contents of food packaging nitrogen can also play a good protective role; the crunchy food prevents extrusion; the packaged food avoids unbalanced external pressure together with crimping, thereby making the texture hard; even irregular The shape can maintain an aesthetically pleasing surface of the food packaging, reducing damage to the surface of the packaging material by the deterioration of the food.